ROTARY AIR LOCK VALVE / ROTARY AIR LOCK FEEDER

We, at Ricon Dynamic Engineers design and manufacture one of the most vital products in industrial powder handling process. This are called Rotary Air Lock Feeder. Handling powder material is a very complicated process and unless we discuss and understand our buyers exact requirement, then only we go into the further process. This is our fundamental policy since 1979, when we put our foot into the Rotary Air Lock Valves manufacturing activities.

These valves are available in following configuration with Heavy Duty out Board Bearing:

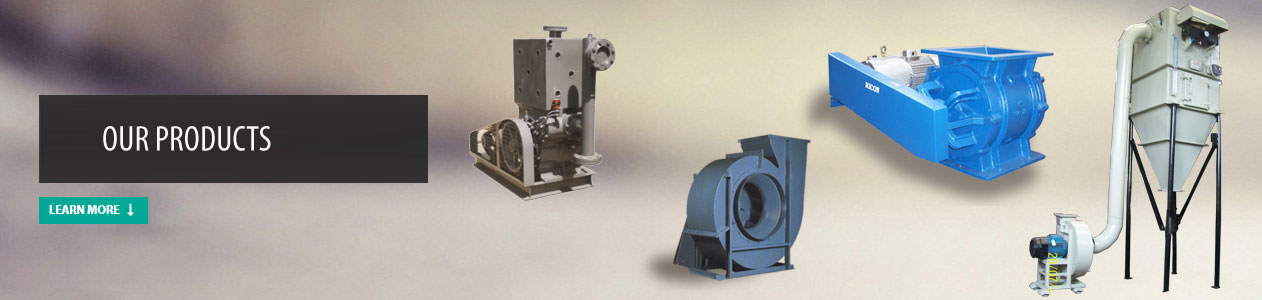

Our clients are our friends and we ask them to give us full feedback of their requirement and then it becomes our responsibility to ensure that they get most efficient Rotary Air Lock Valve from us and that they will not face any problem or worries. Here are the some of the photographs of our RICON Rotary Air Lock Feeder:

Applications :

Rotary airlock feeders have wide application in industry wherever dry free-flowing powders, granules, crystals, or pellets are used. Typical materials include:

Cement

Cement

Ore

Ore

Sugar

Sugar

Minerals

Minerals

Grains

Grains

PVC Chips

PVC Chips

Dust

Dust

Fly ash

Fly ash

Starch

Starch

Guar gum Powder

Guar gum Powder

Flour

Flour

Gypsum

Gypsum

Lime

Lime

Coffee

Coffee

Cereals

Cereals

Pharmaceuticals

Pharmaceuticals

Rotary feeders are ideal for pollution control applications in wood, grain, food, textile, paper, tobacco, rubber, and paint industries. The Standard Series works beneath dust collectors and cyclone separators even with high temperatures and different pressure differentials.

Our valves are available in size 100 mm to 750 mm on regular basis with material of construction like Cast Iron, Cast Steel, Cast SS 304, 316, 316L etc.

These valves can handle 2 liter /revolution to 425 liter /revolution, i.e. 1 TPH to 300 TPH.